DIATEST News

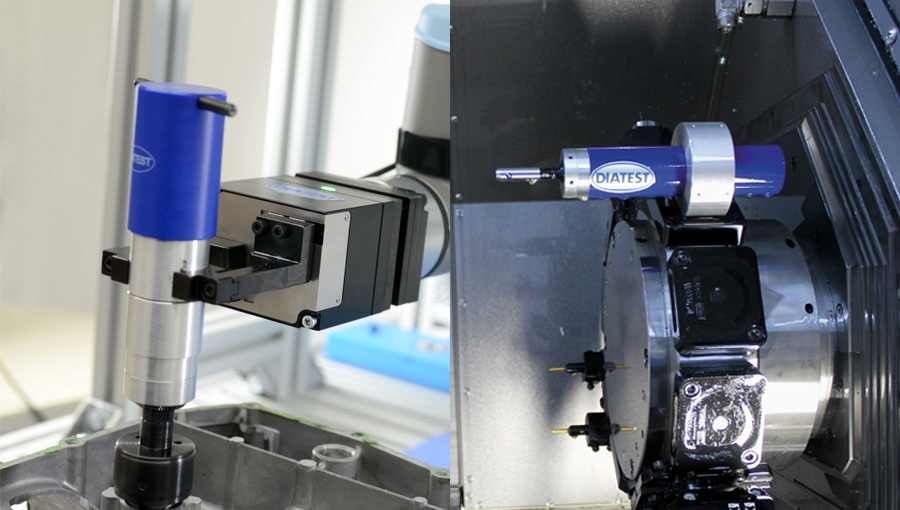

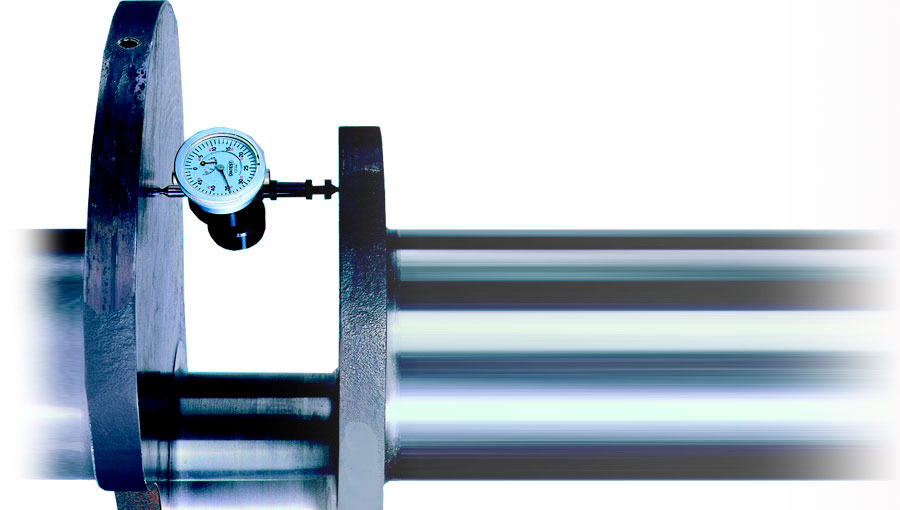

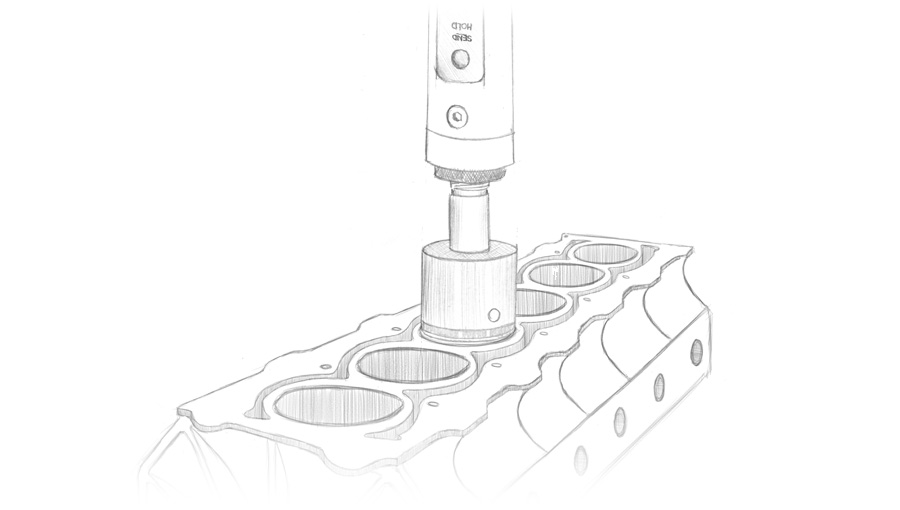

Some impressions from the international track tour 2024

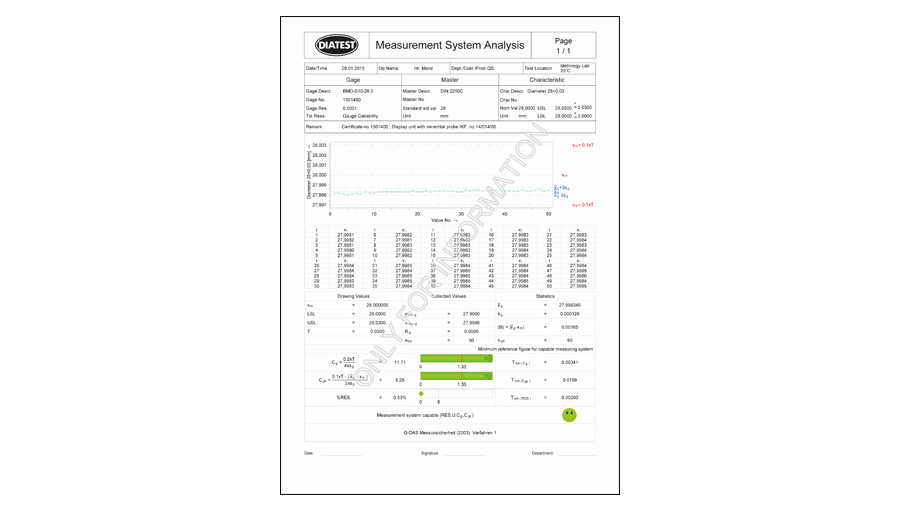

10th International Conference on Production Metrology September 3, 2024

Campus Buchs, Ostschweizer Fachhochschule

Visit DIATEST at the Show AMB in Stuttgart, Germany

from 10.09. to 14.09.2024

DIATEST is represented by: DIATEST Schober GmbH