Automated measurement and complex measurement solutions

Dynamic in-process measurement (IPM) in the machining centre

Automatic measurement in the process (IPM)

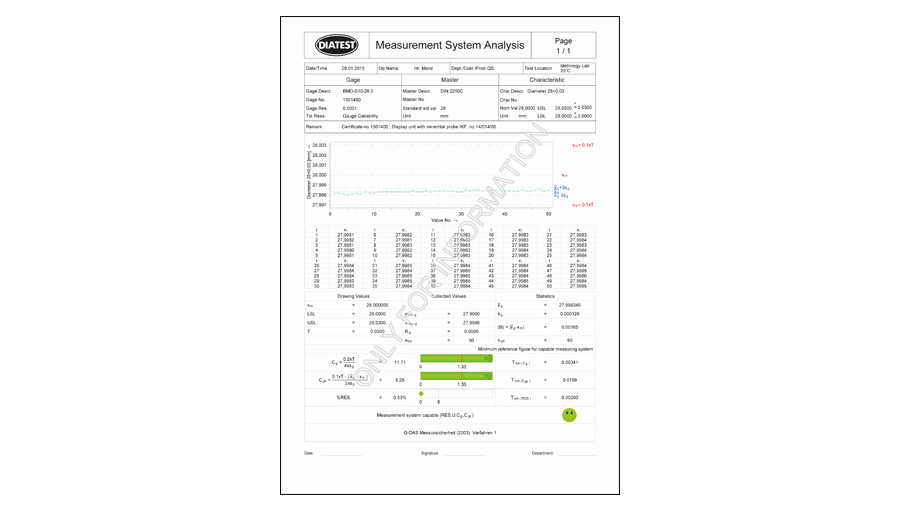

100 % safety – Full process control – Increased good parts

Scrap reduction of up to 50 % compared to conventional in-process checks

The measuring is done:

- With the right measuring tool

- Without external influences

DIATEST IPM – Dynamic and static measurement in the process!

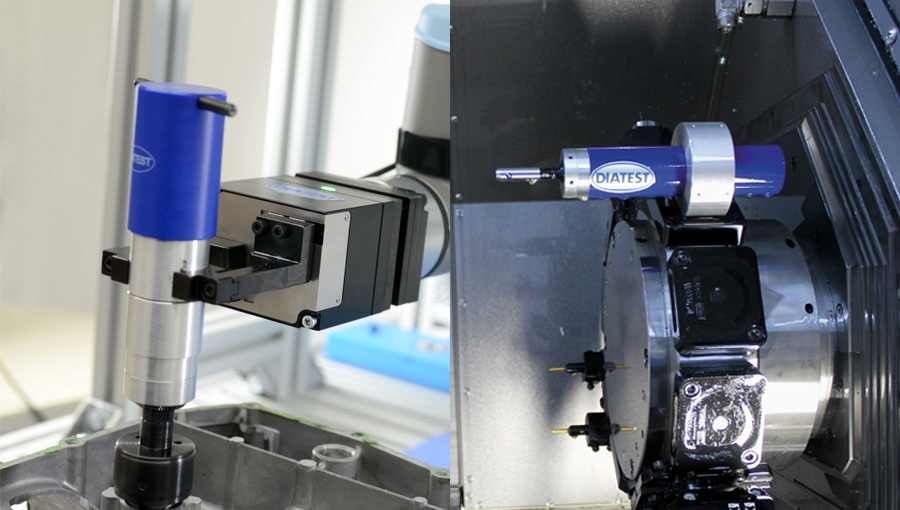

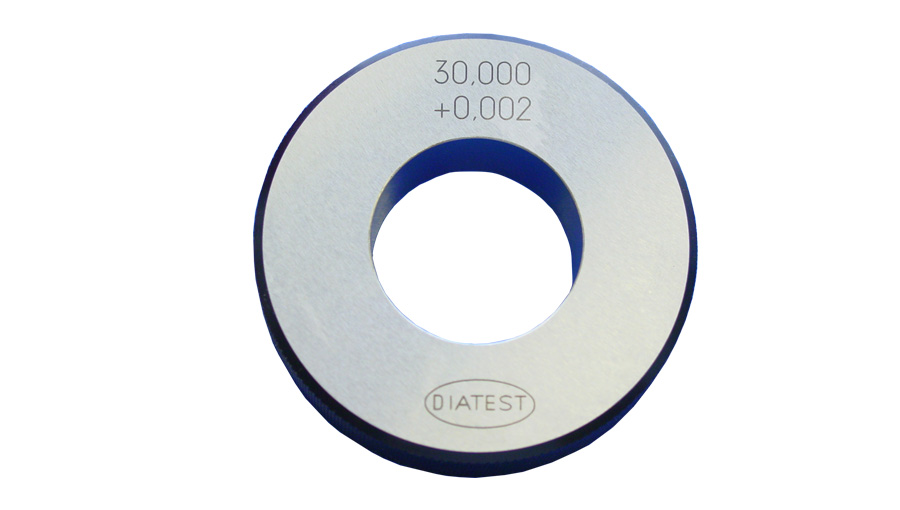

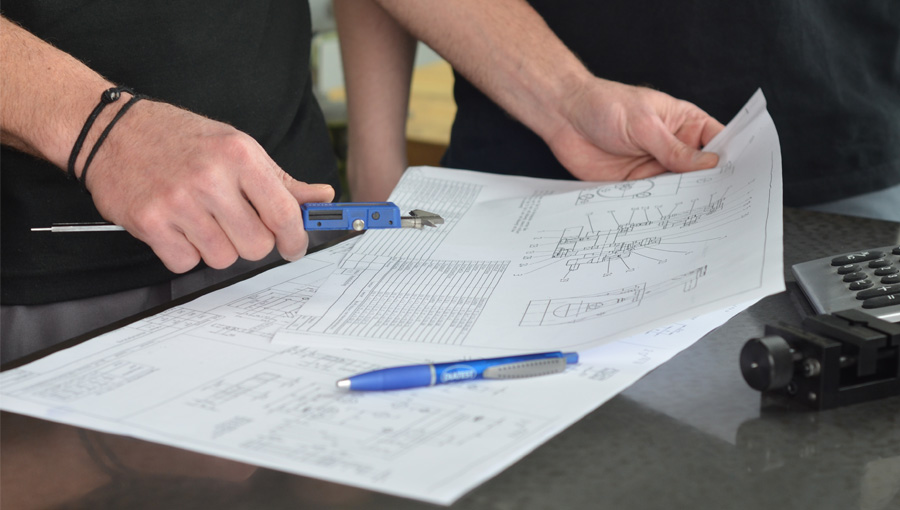

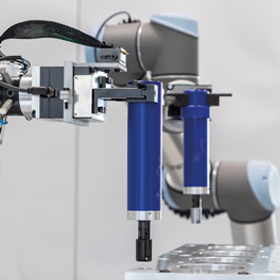

The IPM is a measuring system with radio for use in machining centres. The system consists of a

- DIATEST bore gauge (BMD),

- a radio module.

Both are permanently installed in a tool holder (e. g. HSK)

It transmits measurement data by radio to a PC, for example.

Consistently high quality – an invaluable competitive advantage

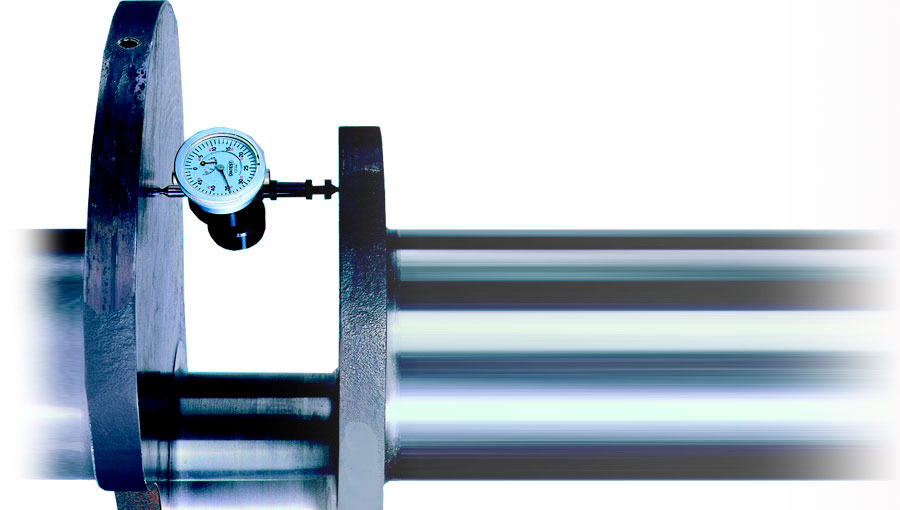

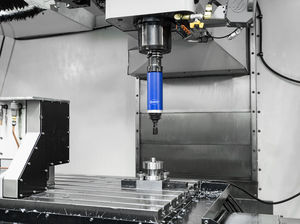

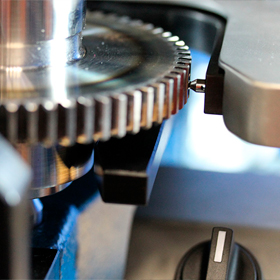

Measuring directly in the machining centre combines the manufacturing process and quality assurance:

- The IPM measures high-precision, critical and safety-relevant bores directly in the manufacturing process.

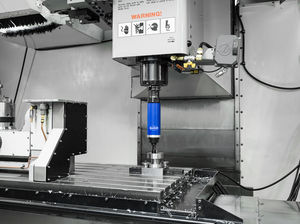

The flexible DIATEST IPM measuring system uses the full functionality of a machining centre.

Set up and move on!

The IPM sits in the tool magazine of the machine

- Once set up, the IPM works autonomously

- Integration is independent of the machine manufacturer

You can find more information here!

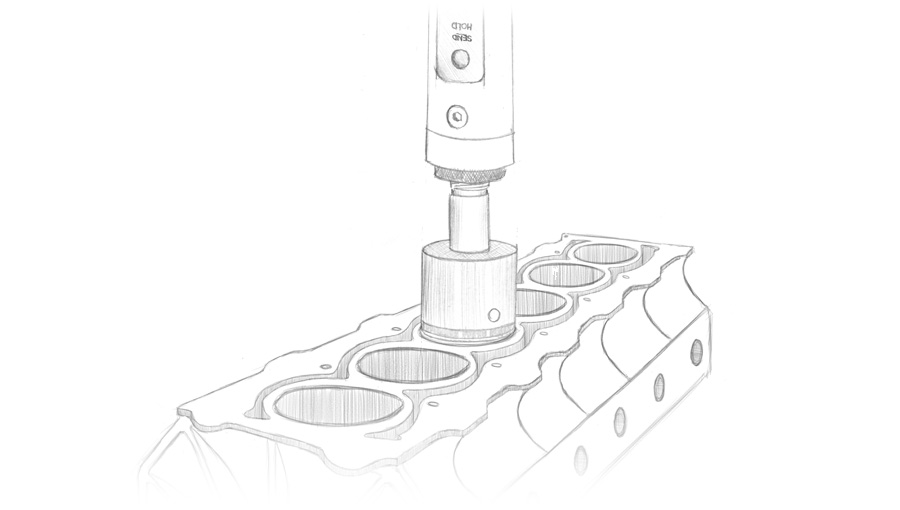

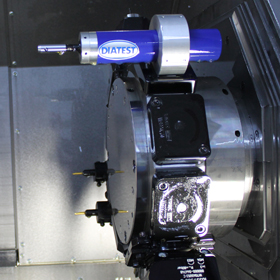

Example in a multi-spindle CNC machine: The DIATEST wireless probe holder and the DIATEST BMD

- are automatically moved into the workpiece,

- clean the bore with compressed air before each measurement,

- measure dynamically on several levels,

- transmit the measurement data via real radio at each measurement level.