- © 2025 Diatest

- |Imprint

- |General terms

- |Protection des données

Directly to product (Quick Selection)

- Adaptateur

- Capteurs Analogiques MTD

- Comparateurs Analogiques MU et Comparateurs à secteur pour la mesure de diamètres

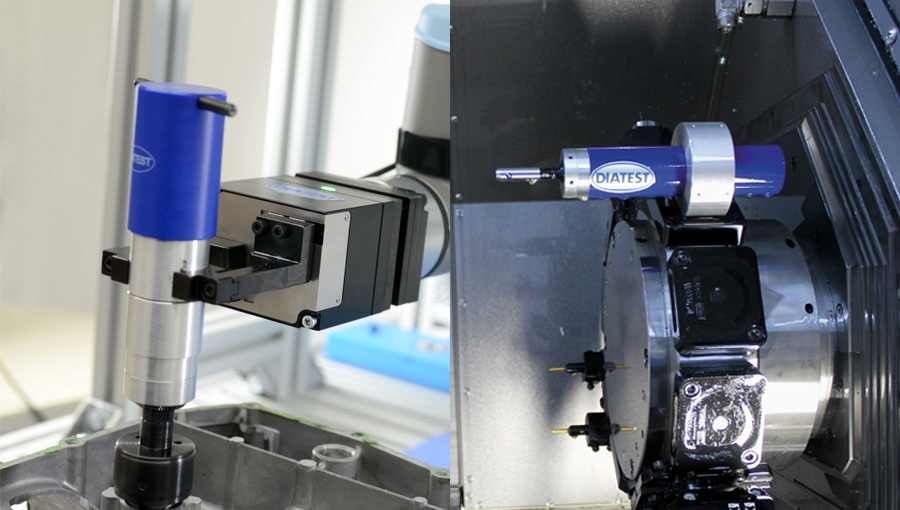

- Mesure dynamique en cours de processus (IPM) dans le centre d'usinage

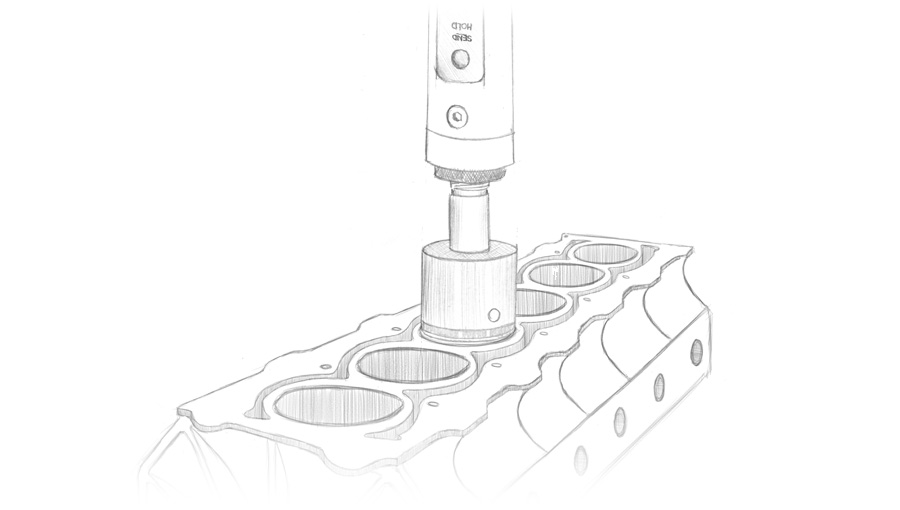

- BMD – Tampons de Mesure DIATEST

- BMD-XQ

- Salles d'étalonnage des classes de qualité 1 et 2

- Certificats

- Mesureurs de chanfreins

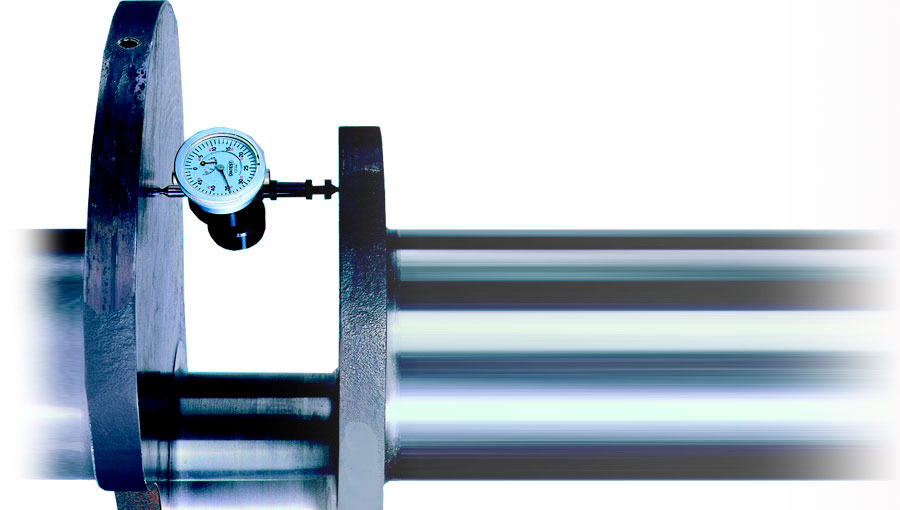

- Appareil de contrôle de vilebrequin KP

- Statifs de mesure

- Rallonges de Profondeur

- Butées de profondeur

- DIA-COME

- DIA-COME (pour mesure de denture)

- DIA-Safestore

- DIATRON1500-S

- DIATRON2200

- DIATRON6060-µNetwork

- DIATRON MultiFire

- DIAWIRELESS

- Comparateurs Digitaux MDU pour la mesure de diamètres

- Instrument de mesure de diamètres extérieurs AMG

- Instruments de mesure de denture extérieure EG

- Supports flottants

- Pour les mesures simultanées du diamètre et de la profondeur d’un alésage lisse : Gauge-2Dimensions

- Hardware

- Instruments de mesure de denture Intérieure

- Supports de comparateur

- Accessoires, têtes de renvoi et supports pour intégration dans montages de contrôle

- Maintenance et réparation

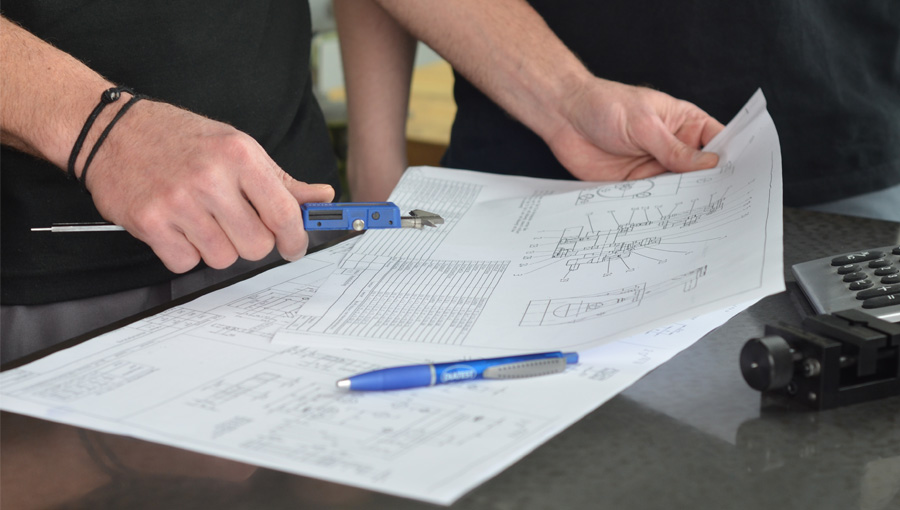

- Appareils de mesure

- Services de métrologie

- Autres accessoires et pieces détachées

- Indicateurs d’alésage

- Renvois d’angle

- Mesure automatique assistée par robot

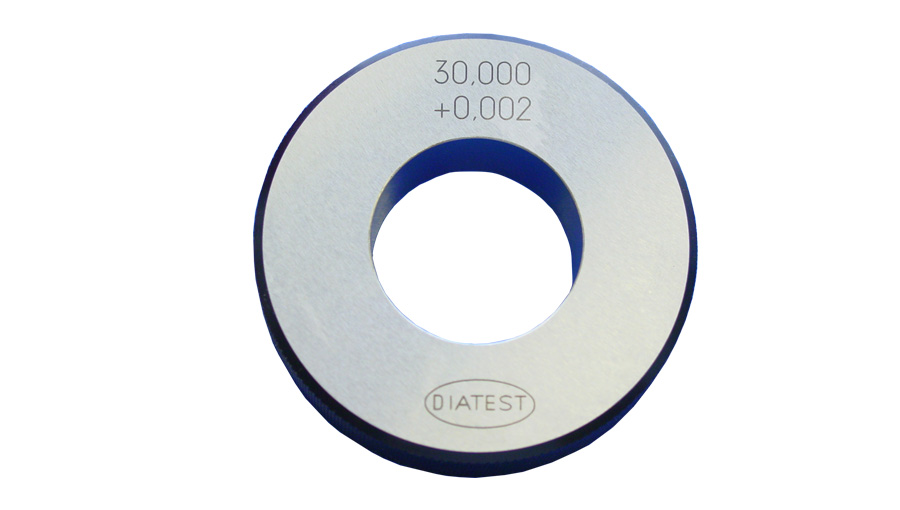

- Etalons de réglage / Dispositifs d’étalonnage

- Bagues de réglage

- Simultanément : mesure de la profondeur et contrôle « Entre/Entre-Pas » d’un alésage lisse ou d’un filetage intérieur.

- Accessoires Spéciaux

- Marquage Spécial

- Logiciel

- Tête de Mesure

- TD-Gauge+ MOTORIZED

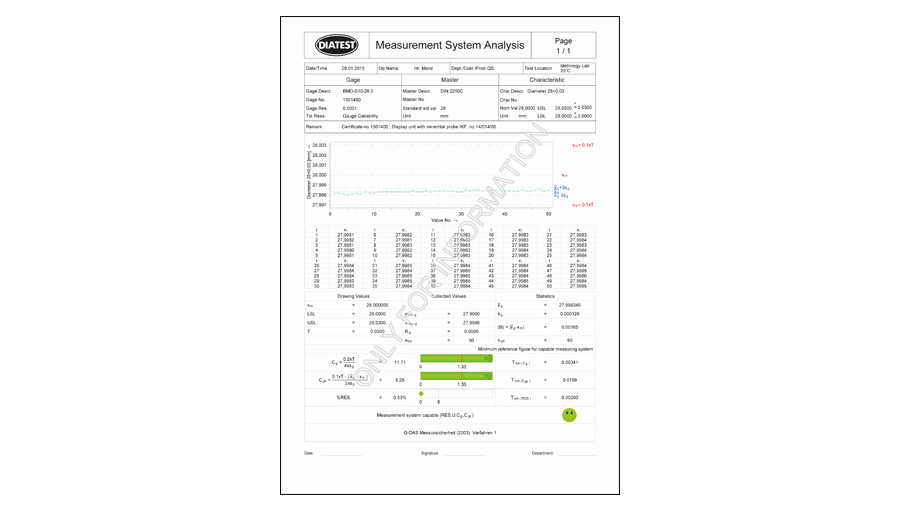

- Test report VDA volume 5

- Transfert des valeurs mesurées par câble